In the Competitive World of Product Packaging Clarity, cost-efficiency, and durability often top the list of priorities for manufacturers. One material that continues to check all these boxes is General Purpose Polystyrene (GPPS). Known for its high transparency, rigidity, and excellent processability, GPPS is quickly becoming the go-to solution for industries seeking reliable and aesthetically appealing clear plastic containers. Whether you’re in food packaging, medical supplies, or consumer goods, using GPPS for packaging offers significant performance and economic advantages.

Exceptional Clarity for Enhanced Product Visibility

One of the defining features of GPPS is its glass-like transparency. This makes it ideal for clear plastic containers that need to showcase their contents attractively. From disposable cups and lids to cosmetic jars and retail blister packs, the clarity of GPPS enhances product appeal and helps consumers make quicker purchase decisions. The improved shelf visibility also contributes to stronger brand recognition, especially in sectors like food, cosmetics, and health supplements.

Versatility Across Packaging Formats

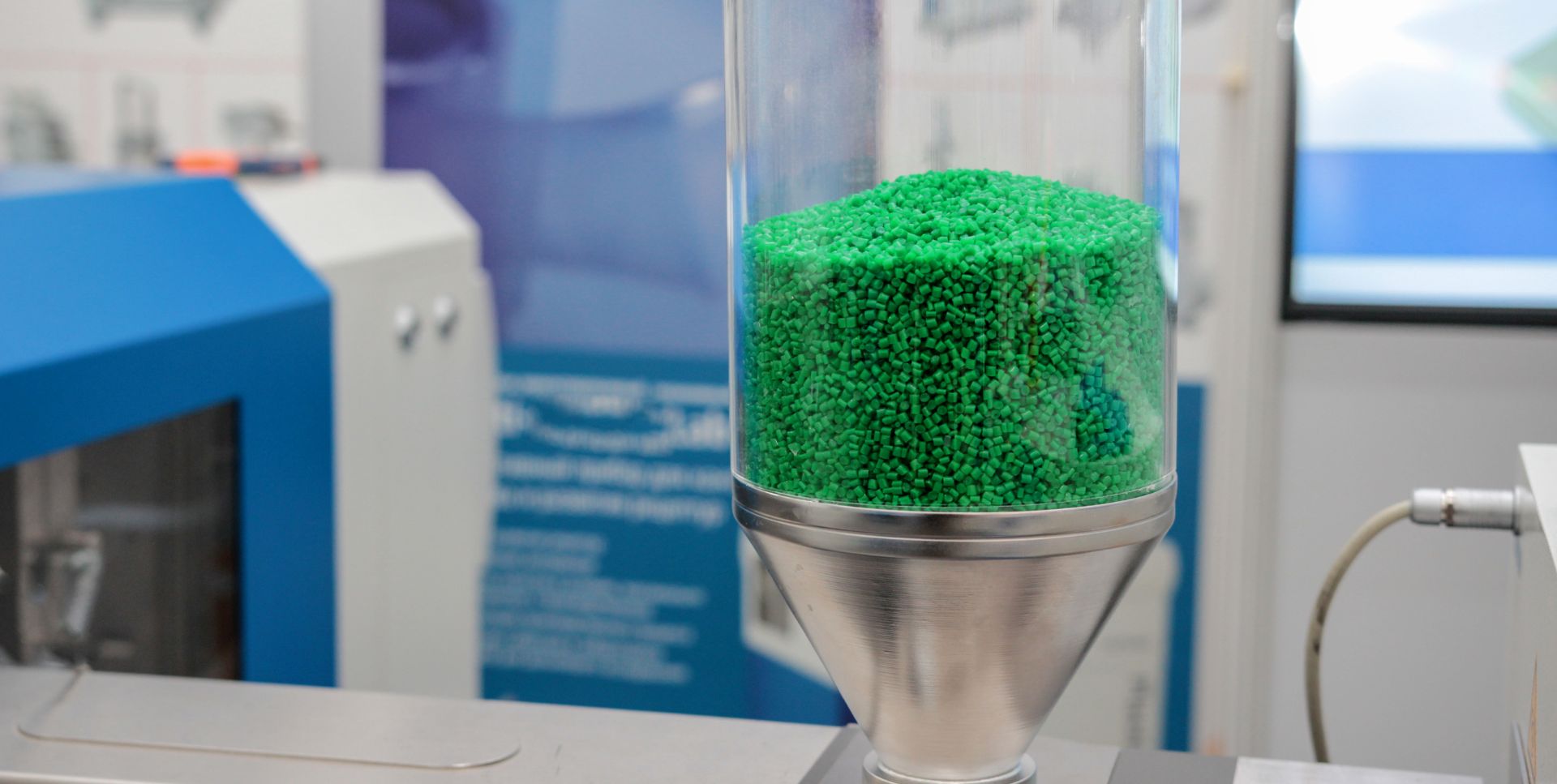

GPPS is highly adaptable and supports multiple processing techniques, including extrusion and injection molding. Its versatility allows manufacturers to produce everything from thin-walled clamshell packaging to rigid trays and compartmentalized boxes. Because of its consistency in molding and dimensional stability, GPPS is especially favored in automated packaging environments that demand precision and high-volume throughput.

For businesses looking to scale without compromising on product integrity, choosing the right GPPS suppliers can make a significant difference. Consistent resin quality leads to fewer defects, reduced material waste, and shorter cycle times on the production floor.

Cost-Effective Without Compromising Quality

In large-scale manufacturing, every gram counts. GPPS offers a lightweight yet strong packaging solution, which translates to reduced raw material costs and lower shipping expenses. Unlike some high-cost engineering plastics, GPPS delivers a balanced combination of mechanical strength and economic efficiency—making it the smart material of choice for budget-conscious production teams.

Moreover, GPPS is recyclable and widely accepted in global recycling systems, which adds another layer of value for companies focused on sustainable packaging practices.

Safe for Food and Medical Packaging

GPPS grades developed for food contact are compliant with global safety standards, making them suitable for food trays, yogurt cups, cutlery, and more. In the medical field, GPPS is used in disposable labware and diagnostic kits due to its chemical resistance and dimensional precision. The material’s inert nature ensures that it does not leach harmful substances, making it a safe and trusted choice.

Choosing the Right GPPS Supplier

Not all GPPS is created equal. The performance of your packaging products depends significantly on the quality of the raw material. Trusted GPPS suppliers offer a variety of grades optimized for different applications—ranging from high-flow injection molding variants to extrusion-specific grades. Working with a supplier that provides technical support, consistent material quality, and timely delivery ensures that your production line never misses a beat.

Conclusion

In today’s fast-paced, quality-driven packaging industry, GPPS has carved a niche for itself as the ideal material for clear plastic containers. Its superior clarity, ease of processing, cost-efficiency, and safe usage profile make it a reliable and versatile material for manufacturers across sectors. If you’re aiming to enhance product visibility while keeping operational costs in check, GPPS for packaging should be your material of choice.