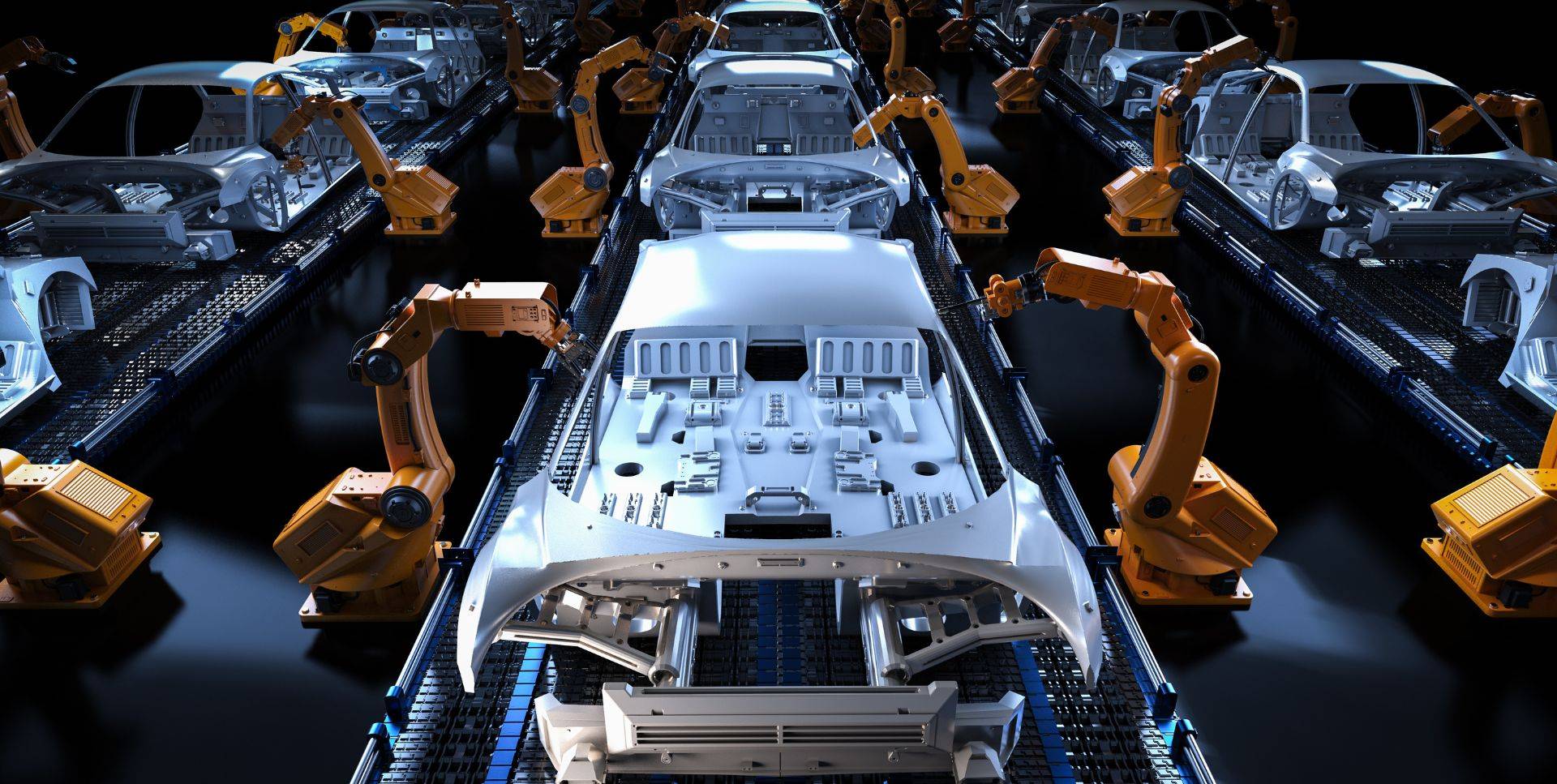

ABS: The Backbone of Modern Automotive Interiors when it comes to building modern automotive interiors, manufacturers are constantly on the lookout for materials that balance strength, style, durability, and thermal stability. Acrylonitrile Butadiene Styrene (ABS) is one such material that continues to dominate the industry. From dashboard components to trim panels and seat backs, ABS has established itself as the gold standard for performance and aesthetics in automotive applications.

This blog explores why using ABS for automotive interiors offers unmatched benefits, and how the right grade of this thermoplastic can elevate both functionality and design.

Durability Meets Design in Dashboard Applications

One of the most common uses of ABS is in the manufacturing of dashboards and instrument panels. These parts are central to a vehicle’s cabin, requiring exceptional surface quality, dimensional precision, and the ability to withstand temperature fluctuations. Dashboard plastic made from ABS delivers excellent resistance to cracking, impact, and UV exposure, making it ideal for long-lasting performance in both hot and cold climates.

Moreover, ABS offers a smooth finish that can be textured, painted, or chrome-plated—allowing automakers to create interiors that are both functional and visually refined.

Heat Resistance and Structural Strength

Automotive interiors are exposed to direct sunlight, high cabin temperatures, and long operational hours. That’s where heat-resistant ABS grades play a vital role. These specially formulated resins retain structural integrity even when temperatures exceed 90°C, ensuring safety and comfort in real-world driving conditions.

ABS combines the stiffness of acrylonitrile and styrene with the toughness of butadiene rubber. This unique balance results in a material that can absorb impact, resist deformation, and maintain form—ideal qualities for automotive trims, pillar covers, seat shells, and console housings.

Ease of Processing and Design Flexibility

ABS is favored not just for its performance, but also for its ease of manufacturing. It supports injection molding, thermoforming, and even extrusion, making it suitable for mass production with excellent dimensional control.

With ABS for automotive manufacturing, designers can create complex geometries with consistent wall thickness, tight tolerances, and seamless assembly integration. This flexibility allows for the creation of lightweight, high-performance parts without sacrificing design innovation.

Applications of ABS in Vehicle Interiors

Here are just a few ways ABS is used in today’s automotive interiors:

- Dashboards and upper panels

- Door trims and pillar covers

- Center consoles and glove boxes

- Seat back covers and armrests

- Air conditioning vents and switch panels

Whether it’s a passenger vehicle, SUV, or commercial vehicle, ABS provides the perfect balance of appearance, reliability, and safety.

Benefits of ABS Over Other Plastics

Compared to alternatives like polypropylene or PVC, ABS offers a superior combination of mechanical strength, surface quality, and heat resistance. For manufacturers prioritizing both appearance and durability, ABS is the go-to choice.

| Feature | ABS | PP | PVC |

|---|---|---|---|

| Heat Resistance | ✔✔✔ | ✔✔ | ✔✔ |

| Surface Finish | ✔✔✔ | ✔ | ✔ |

| Impact Strength | ✔✔✔ | ✔✔ | ✔✔ |

| Paint/Chrome Compatibility | ✔✔✔ | ✔ | ✖ |

Conclusion

The continued success of ABS in automotive interior manufacturing is no accident. With its unbeatable combination of thermal stability, strength, finish, and ease of processing, ABS remains the material of choice for OEMs and Tier 1 suppliers. Whether it’s a luxurious dashboard or a robust seat cover, dashboard plastic made from ABS ensures that your vehicle’s interior performs as well as it looks.